Reviewers on YouTube have made disassembling knives very popular (much to the chagrin of many knife manufacturers I’m sure).

No one is more guilty of this than Nick Shabazz — though his disassembly videos are a public service to teach those about the inner workings of the knife and general maintenance.

You’ll likely notice that when Nick and others put knives back together, they use a substance called Loctite on the screws.

So what exactly is Loctite and is it really necessary to use when putting a knife back together? Read on.

What is Loctite?

Loctite is the brand name for a threadlocker. Loctite is to threadlocker what Kleenex is to facial tissue or ChapStick is to lip balm. Although Loctite is the most popular threadlocker, there are other brands available like Permatex.

Loctite itself comes in a number of different forms, but the two most popular methods for application on knives are liquid-form or wax-form.

Some more scientifically minded person could tell you the contents of the various Loctite formulas, but I believe they are single anaerobic adhesives. It is a thread-locking fluid meant to be applied to screws and bolts to keep them from coming loose.

Loctite will remain in liquid form while it is exposed to oxygen. But when it becomes sealed from oxygen between a screw and a metal frame, it will cure in about 24 hours.

How to Apply Loctite

To use Loctite on a knife, you simply apply a small amount to the screw. Using a toothpick to help spread it out in the threads is helpful if you’re using the liquid. Otherwise, a dab of the wax-form of Loctite is more than enough. The substance fills the microscopic grooves of the threads.

Then screw it back in at the right torque. If you’re using it on the pivot, make sure the pivot is properly torqued with no blade play or centering issues in a timely manner.

Once everything is set, you want to let it cure for at least 24 hours. This allows the Loctite to harden and work as intended. This should prevent the screw from coming loose through vibrations and general use.

Red Loctite vs. Blue Loctite

One important thing to note is that there are various types of Loctite. Here’s a quick breakdown of some of the most common Loctite formulas used in knives.

Loctite Red 262

Red Loctite is essentially permanent threadlocker because it can take considerable strength to remove a screw that’s been cured with red Loctite. At that point, you’ll likely strip your screws trying to remove it.

This type of threadlocker has been frowned upon by knife people. A few years back, Spyderco came under fire after it used high strength red Loctite on its screws. It eventually promised to move to blue Loctite.

Loctite Blue 242

Blue Loctite is the sweet spot when it comes to strength. It’s strong enough to keep a screw in place without becoming too difficult to remove.

This is the type of Loctite knife nuts recommend using and has become essentially industry standard.

Loctite Purple 222

Although far less common, purple Loctite is recommended for use on smaller screws — less than 1/4″. Smaller screws can be more susceptible to stripping, and purple Loctite is not as strong but offers enough adhesion for regular use.

Is it Really Necessary?

Now we come to the big question: to Loctite or not Loctite.

To be honest, this is mostly a matter of preference and personal experience. Here are three common stances.

1) Some people don’t use it because the screws on their knives never come out on their own. This may be because the manufacturer already used Loctite, they have a good quality knife with good screws, or their use has simply never warranted it.

2) Some people put Loctite only on the knife pivot. The pivot is the screw that you really want set properly, especially because there is usually a sweet spot between too loose and too tight. If you find that right spot, using Loctite on the pivot will help keep it there even when you open and close the knife repeatedly.

3) Some people Loctite every screw. To some, the assurance that no screws — not in pivot, on the pocket clip, or anywhere else — will come loose is vital.

Risks of Loctite

There are some small risks of using Loctite.

First, if you use red Loctite you can cause a big problem. A knife can become permanently stuck and cause stripped screws. As I explained before, a soldering iron could work to help break the Loctite but some people try it when it’s already too late.

Second, even with blue Loctite, it’s way too easy to go overboard with applications.

For example, take a look at Nick Shabazz’s disassembly of the Cold Steel AD-15 to see what happens when someone puts a bit too much Loctite (Nick doesn’t do it):

Even though it’s easy to remove with some force, it can cause issues.

Third, Loctite requires some cleaning before reapplication. It’s not a big deal, but it does require some time and effort.

Fourth, too much Loctite can cause leakage into other parts of the knife and require yet another teardown.

Finally, Loctite requires about 24 hours to fully cure. However, sometimes people can be a bit too impatient and start messing with a knife too much after applying the blue Loctite. This doesn’t result in any major problems, but it can lead to inefficiencies in the curing process and cause the screws to loosen prematurely.

Alternatives to Loctite

Some find Loctite to be ineffective or simply prefer not to use it because it can stain. Here are some alternatives.

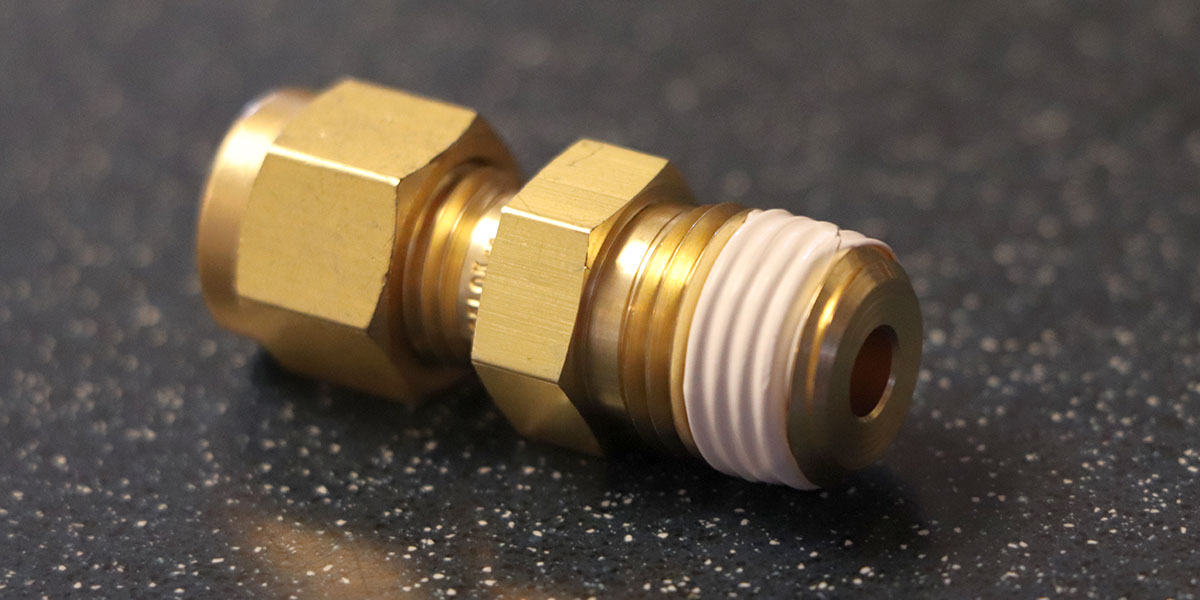

Teflon tape

Example of teflon tape

I’ve heard great things about teflon tape — sometimes known as plumbers tape. Instead of applying a liquid, you just wrap the tape around the screw and tighten. It is most commonly used in plumbing, but it works surprisingly well on knives. I would say this is the most popular alternative to Loctite.

Nail polish

Yup, a fair number of people say that nail polish works as a threadlocker as well, particularly on smaller screws. I’ve heard other things in similar veins like white out, but you should be cautious with these methods.

Let us know if you have any other thoughts or suggestions on Loctite or threadlockers in the comments.

January 31, 2021 at 12:02 am

thanks for the info, really usefull

March 30, 2022 at 1:35 pm

Good article! Thank You!

June 5, 2022 at 4:10 pm

I just learned about loctite from a review that suggested using it to secure traction pins in pedals for a bicycle. Warning that if you didn’t use it they would surely fall out. Your explanation was very thorough and helpful. I now know why I should use it and which type to buy. Thank you!

January 10, 2023 at 3:01 pm

I often disassemble brand new knives, put a dab of blue thread locker on each screw, and reassemble. Reason being, I HAVE had screws loosen, fall out, and be lost on their own, on fairly new knives.

YMMV.

January 16, 2023 at 8:55 am

As Dianne T. said in an earlier comment here, “Your explanation was very thorough and helpful.” Thank you!