It’s happened to almost all of us.

You get a brand new framelock folding knife in the mail and eagerly engage it. Everything seems fine as the knife opens smoothly and effortlessly. But, just as you’re closing it, you notice the framelock is extremely difficult to disengage.

This is known colloquially as lock stick.

Unfortunately, it’s an all-too-common issue in framelocks and even liner locks. The good thing is that there are several ways to go about fixing it.

What Causes Lock Stick?

In the most basic terms, lock stick is when a framelock or liner lock feels sticky when trying to unlock it. This makes it more difficult and sometimes even painful to disengage.

That’s the definition of lock stick, but what actually causes the major knife annoyance?

Galling

The cause of the issue is multifaceted. One of the reasons has to do with the lockbar material and the blade steel. Lock stick happens most prominently in knives with titanium handles because titanium is susceptible to galling and tends to stick to dissimilar metals.

For example, if you have a titanium lockbar contacting with the tang of an S35VN blade, they have the tendency to stick to one another. That’s why this issue isn’t reserved only for budget knives but also affects pricier ones.

This essentially boils down to microscopic metal-on-metal friction.

Lock Geometry

Spyderco Brouwer like many modern knives have lockbar inserts to prevent lock stick.

Another is the actual lock geometry. There’s a delicate balance between just how much a lockbar should interface with the tang of the blade. In some cases where too much of the lockbar is touching the blade tang, it could cause lock stick. Knifemakers have to find the right amount and sometimes they get it wrong.

The culprit may be the angle of the blade tang or the angle of the lockbar face.

Lockbar Tension

Some have also said the amount of tension on the lock is another cause of lock stick.

If the tension of the lockbar is too high, it will want to wedge itself against the tang a bit too much. Some people refer to this as lock stiffness rather than lock stickiness, but I believe it falls under the same purview.

Dirt and Oil

Finally, a very common reason for lock stick is the presence of oil or dirt on the surfaces of the lockbar and blade tang. This type of lock stick develops over time, mostly from regular use as stuff gets stuck to the surfaces.

This YouTube video goes into a bit more detail about some of the factors.

How to Fix Lock Stick

Now that you know what it is, let’s get onto actually fixing the issue of lock stick.

There are a few methods that have worked for different people, so I thought I’d break them down a little bit more.

Clean the Tang and Lockbar Surfaces

As I said before, a common reason for lock stick is dirt or residue on the tang of blade or the surface where the lockbar makes contact with the tang.

An easy way to fix this lock stick is to give these surfaces a good clean. If you want to give it a thorough cleaning, I highly recommend taking it apart so you can really clean the lockbar. But you can also put some rubbing alcohol or other preferred cleaner in while the knife is closed.

This alone will oftentimes fix the issue, particularly in older knives.

The Pencil Method

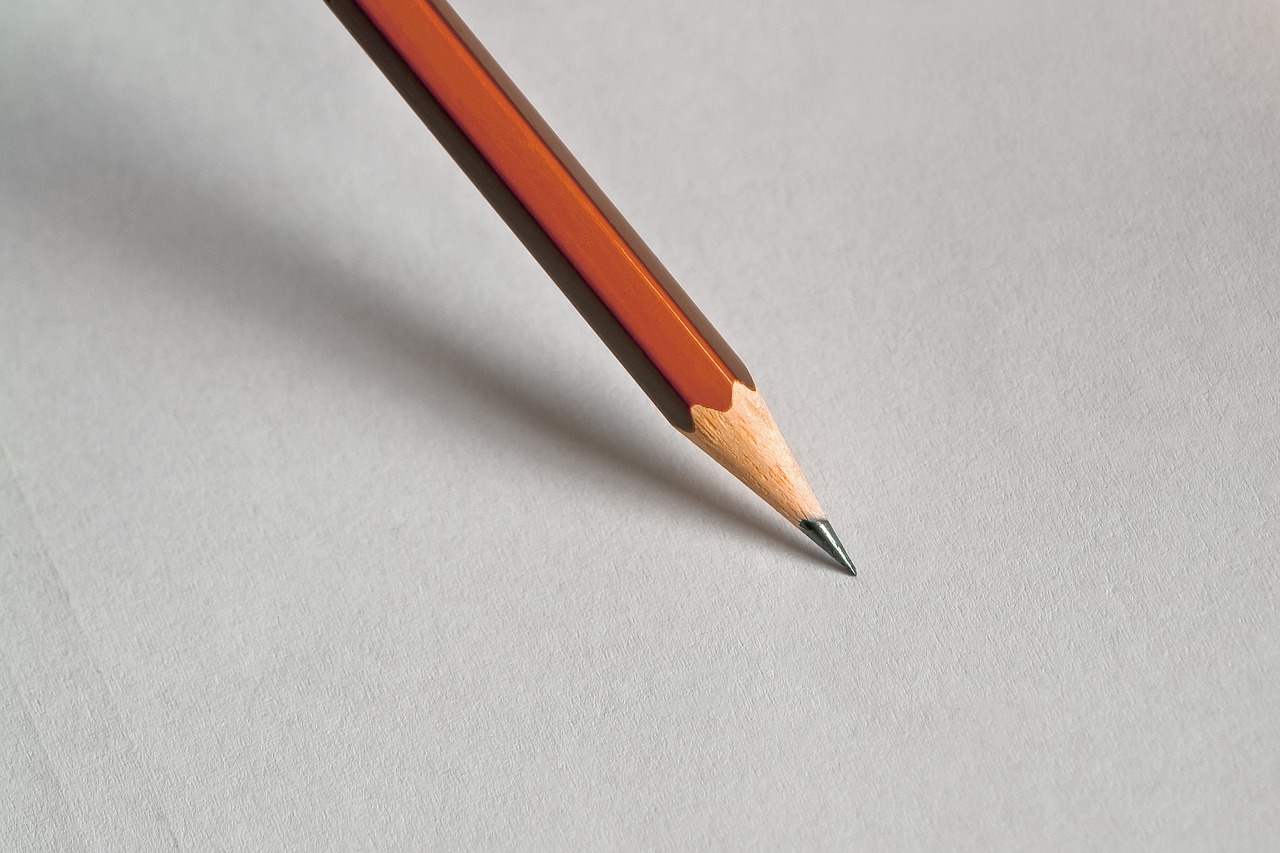

If cleaning it fails, there’s the old pencil method. This involves taking a classic No. 2 pencil and coloring the lock face of the tang and the lockbar face.

The writing part of the pencil is actually graphite. What this does is lubricates the surfaces of the lock to help reduce the friction from galling. You don’t want to overdo it, of course, because it could cause lock slip.

This can be a temporary solution that requires reapplication after a while. However, it will make it easier to break in the lock and you may need to apply graphite less frequently over time.

The Sharpie Method

This works the same as the pencil method, except you use a permanent marker on the lock faces.

Some people swear one works better than the other. I tend to go with the pencil because the Sharpie is bolder and can ruin the aesthetics more.

Again, you may need to reapply the Sharpie after a few uses.

Break It In

If you don’t want to put anything on the lock faces, you can break it in the old-fashioned way: with a lot of opening and closing. In some cases, simply opening and closing the knife will reduce the friction of the metal and essentially cause some polishing of the surfaces.

The major downside is the sheer effort it takes to do this. Without some substance to soothe the issue, the lock stick can shred your thumb after a few times trying to close it.

You might want to invest in some gloves.

Anti-Oxidant Compound

Another thing some swear by is anti-oxidant compound commonly used by electricians.

This type of substance, which can be found at your local hardware store or Home Depot, is specifically designed to reduce galling in metals.

Unlike the pencil and Sharpie method, you don’t need to reapply this too many times. Just use a small amount.

Here is Nick Shabazz talking about it a few years ago:

I haven’t heard Nick mention this stuff again in recent videos, so that might not be the best endorsement.

Get It Carbidized

In many cases, knifemakers will carbidize the lockbar face to help minimize lock stick and provide an extra layer of wear resistance.

However, not all titanium framelocks are carbidized. If it’s not, you can send it to someone to get carbidized. I don’t recommend doing it yourself unless you have extensive experience in knifemaking. But if you’re at this stage of desperation with a new knife, I suggest moving onto the final recommendation for fixing lock stick.

Send it Back

If your new knife has lock stick, don’t be afraid to send it back. This is especially true if you bought a knife that cost more than your first car. While it could just need time to break in, you shouldn’t always have to do it on a knife that’s so expensive.

Even if the knife is budget-friendly, you shouldn’t have to stand for a lock stick. Use your right as a consumer to get the knife you want.

Let us know your recommendations in the comments.

April 23, 2019 at 3:09 pm

This is a little off subject, but I use WD-40 occasionally. It helps make the opening and closing easier.

Thanks for the great lock stick advice. It’s happened to me several times.

April 23, 2019 at 4:07 pm

Very valuable bit of information I was seeking so thanks it couldn’t have come at a better time and I am surprised I haven’t heard this recommended before in my YouTube travels because the problem seems to be a fairly prevalent one. Thanks

April 23, 2019 at 9:00 pm

First of all, I had a problem with a Schrade fixed blade knife not fitting properly into it’s sheath. There was poor retention and they sent me another sheath. And I was told if that did not work then to send back the knife as the fault would be with the blade. I had a similar problem with a CRKT and they also sent me a replacement sheath.

Trust that the company will treat you right…. until they don’t. I’ve always been helped and treated well.

I own several folding knives (different brands and models) and I find that if I swing the blade open with a sharp snap that it is harder to disengage. They lock rather tightly when “snapped” open. When I open the blade with it’s flipper or thumb stud they lock just fine and yet are easier to disengage or close.

March 31, 2020 at 3:25 pm

I agree with the snapped open suggestion, I have a case knife that when you snap it open, the lock is much harder to disengage. I used a fine micro file and was able to reduce the strong disengagement .

August 16, 2019 at 6:41 am

Hi there,

I had these issues on a few of my Titanium framelock knives – not on these rather more expensive one where the “lockface” was heat treated though (Sebenzas, Spyderco Techno 1 & 2). These knives’ lockfaces are NOT carbidized but a proper heat treatment that will prevent them from lockstick.

I collect and use many high class folders (CRK, Spyderco, ZT, Böker, DPx Gear…) When I got my first DPx HEST/F Milspec I noticed there was some greyish compound/paste/goo on the blades root (=that part that contacts with the lockface of the titanium lockbar). Some models of the DPx Folders are notorious for lockstick and even “lock rock” (google it). — Mine was perfect – no bladeblay no lockstick no nothing – until I had to clean my knife and wipe and wash away that unidentified goo. The knife was produced assembled in Maniago, Italy by Lionsteel who definitely make great knives! (The newer DPx models “Urban” are made in the USA now). I contacted the Support of DPx and a nice Lady named Linda answered within one business day, telling me that the Italian factory uses LITHIUM GREASE. This stuff worked great and I just ordered it from Amazon. I can really recommend since it works and a professional production knife company uses this! Also they seem to use (but this info is not verified yet) sonething that at least looks like copper paste as the lubrication between the washers and the blade.

March 16, 2021 at 4:41 pm

Anybody try anti-seize?

March 18, 2022 at 11:10 pm

A little artist info… pencils “lead” is made of a combination of clay and graphite. Pencil grades, in average, go from 6H (higher percentage of clay) to 6B. For the most graphite in the mix you want 6B. If you go higher than 6B the manufacturer may add some carbon into the mix, which is not as slippery as graphite.

August 1, 2023 at 10:16 pm

I disassembled a new Cold Steel Luzon and polished the engagement surface of the lock bar to relieve a little lock stick. It probably would have broken in, with some use.

April 9, 2024 at 5:37 pm

Thankyou so much.This came in handy! Pencil worked just fine too.

July 17, 2024 at 5:19 pm

Has anyone tried loosening the tension on the lock bar in a liner lock knife? That is to say, taking the knife apart and bending the lock bar in the opposite direction of increasing the lock bar tension–this would be to the outside of the knife? I hope that someone might have had some experience with this method of taking the lock bar tension down. Thanks very much.

January 2, 2025 at 9:22 pm

I did this very thing with my Al Mar Quicksilver. D2 blade steel on a titanium frame lock. If you choose to go this route, make sure you take careful note of how far over the lock bar reaches without tension on it once the scales are removed. You need a reference point in mind as you adjust it.

For my situation I made the adjustment, reassembled it, tested it, and had to take it apart a second time to get it just right. You certainly do not want to do this more than you must. It is still sticks just a bit but I figure it will break in properly from this point. At least now it is usable.

I am currently working on a Cold Steel Ti-Lite but I think it is just the tang and lock face that need to break in. I cleaned the surfaces and applied some graphite which made it usable.